Key words: SMT equipment, SMT peripheral equipment, JUKI accessories, FUJI accessories, other accessories, SMT whole line scheme

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

About Us

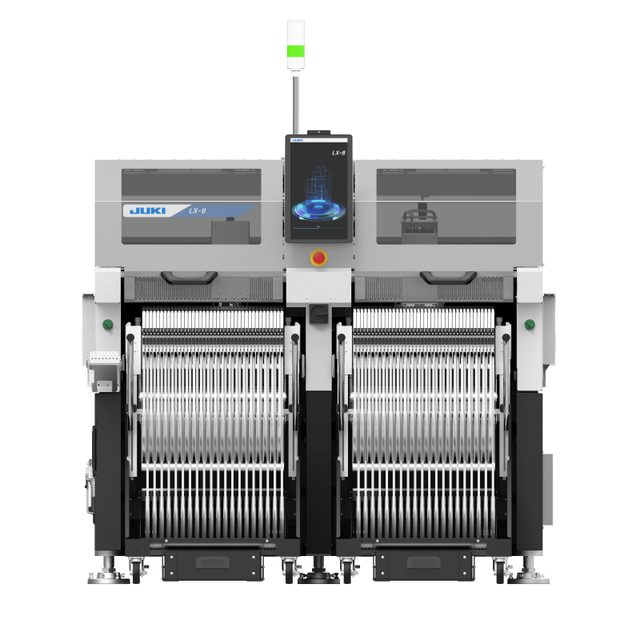

WHO ARE WE

Shenzhen Laiji Mechanical & Equipment Co., Ltd. Established in 2005. is a supplier of SMT whole line equipment. The main business is the sales, leasing, recycling and maintenance services of JUKI / Fuji / Panasonic / Yamaha mounter and peripheral equipment, such as SMT Mounter, Solder Paste Printer, SPI, AOI, Reflow Oven, Laser guided AGV vehicle, Automatic Unloader/Loader,OK/NG Sub Board Machine,X-ray, Counting machine, Automatic Receiving Machine and First article tester!

SMT Complete line equipment supplier

Laiji - professional SMT SMT chip equipment whole line supplier

THREE ADVANTAGES

Three Advantages

Comprehensive Advantage

Well-known brand in the industry, excellent quality

Provide customers with SMT complete line equipment solutions,

SMT placement machine and peripheral equipment sales and leasing,

Such as placement machine, solder paste printer, SPI, AOI, reflow soldering, upper and lower board machines, furnace temperature tester, first piece tester, AGV, etc.

Technical Support

Production team, professional equipment

Deeply cultivated in the SMT equipment industry for 16 years, with well-equipped professional and technical personnel, we can provide customers with a full range of SMT maintenance solutions.

Professional sales and maintenance of JUKI/NXTl ll lll generation CPU box, servo box, control box, monitor, track card,

Lasers, motors, cameras... Existing JUKI/NXT equipment is tested and shipped, spare parts are provided for replacement, and the repair price is excellent!

Service Advantage

Service tenet: "Meet all reasonable needs of customers"

1. Comprehensive after-sales service, can guide the use, and make regular return visits to relieve customers' worries.

2. The quality of the placement machine is three guarantees, which is a product quality problem. During the warranty period, repairs, replacements, and returns are guaranteed, and customers are provided with parts supply.

3. In the course of using the customer, if there is a quality problem that needs to be solved on-site, after receiving the customer's service request

Arrive within 2 hours of Shenzhen; within 8 hours of the Pearl River Delta; within 24 hours of 200 kilometers away.

SMT Equipment maintenance and second-hand placement machine sales

Global Service Hotline

NEWS

FAQ

Q

Detailed explanation of common problems and solutions encountered by SMT Feida

A

1. Communication Failure 1. Circuit Board IC Burnt Out Reason: Feeder Overload, Short Circuit. Solution: Replace the circuit board and update the relevant parameters. 2. Communication Connector Issue Reason: The communication connector may be damaged due to external forces during long-term use, or foreign objects may prevent normal communication. Solution: (1. Check the connector for foreign objects. If present, please remove them. 2. Hardware Failure Feeder cannot be used normally due to improper use or other hardware issues, related images. 3. Power Failure 1. Feeder Not Powered Reason: Power Supply Issues (Plug, Power Switch, Circuit Board Fuse) Solution: (1. Check the communication plug in Figure 1.

Q

What does SMT consist of?

A

In summary, SMT consists of surface mount technology, surface mount equipment, surface mount components, and SMT management. Jiadehe Technology is dedicated to SMT complete line equipment, providing customers with a comprehensive SMT factory solution from printers, pick-and-place machines, AOI to dispensing machines and reflow soldering. Feel free to call for consultation.

Q

What are the main characteristics of SMT?

A

The main characteristics of SMT are high assembly density, small size, and light weight of electronic products. The size and weight of surface mount components are only about 1/10 of traditional through-hole components. Generally, after adopting SMT, the size of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%. It has high reliability and strong shock resistance. The defect rate of solder joints is low. It has good high-frequency characteristics. It reduces electromagnetic and radio frequency interference. It is easy to achieve automation, improving production efficiency. Costs are reduced by 30% to 50%. It saves materials, energy, equipment, labor, time, etc. Jiadehe Technology is committed to SMT complete line equipment, providing customers with a complete SMT factory solution from printers, pick-and-place machines, AOI to dispensing machines and reflow soldering. Please feel free to call for consultation.

PARTNERS

Partner