- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Product display

Contact Us

Phone:0755-23578682

Fax: 0755-23571206

Email:liaojiguang@laiji.com.cn

Address: 2nd Floor, Building C, No. 8, Huanzhen Road, Dabao Industrial Zone, Bogang Community, Shajing Street, Baoan District, Shenzhen

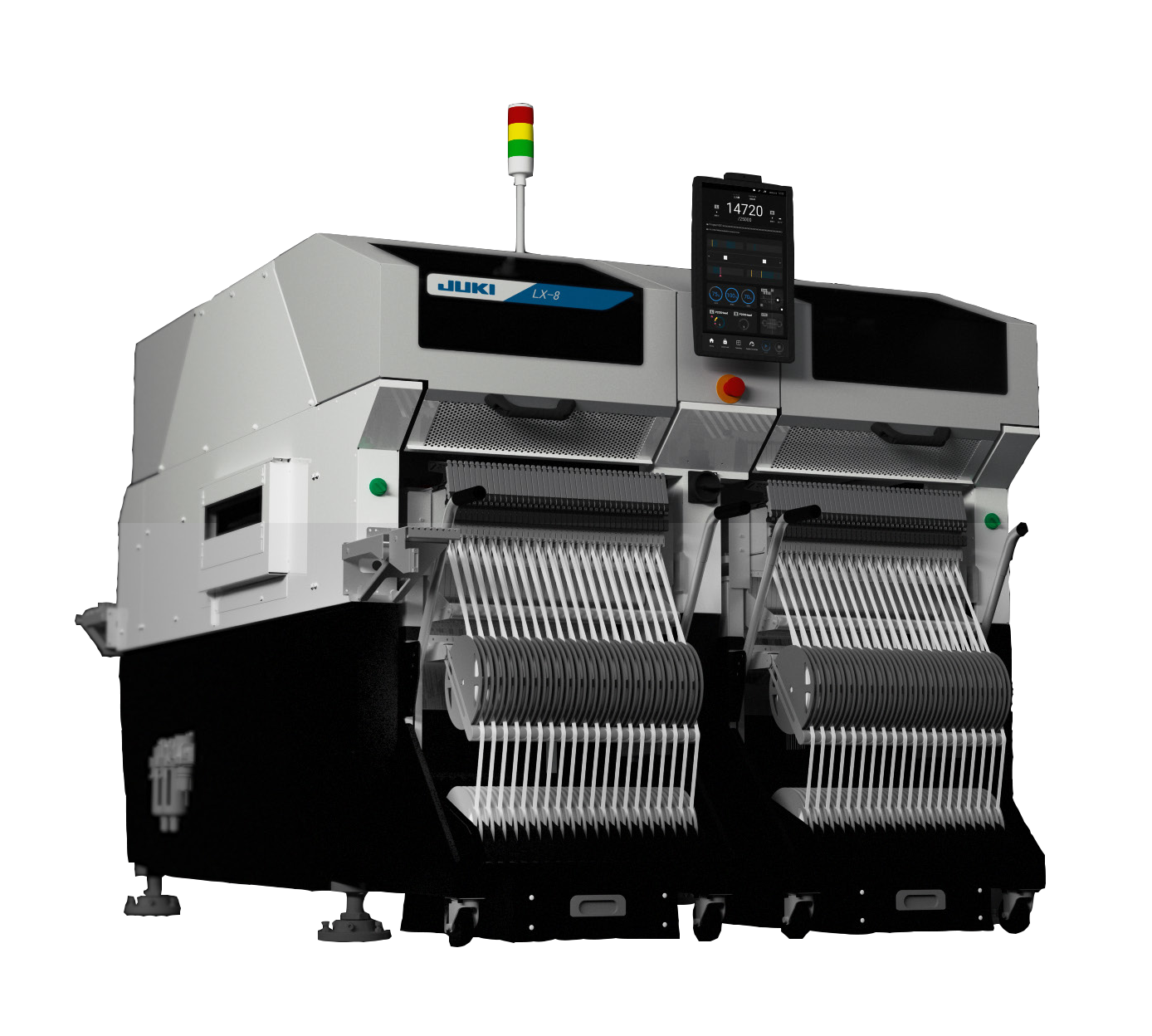

Parallel transfer machine

This equipment is used for SMT production line two-in-one or two-in-one. One-in, two-out and two-in and one-out modes can save labor costs and reduce human contact. The increase in defective products. Front-end loading machine, automatic printing, and SPI transmission are Single-track guide, while the placement machine is dual-track guide, at this time, a one-in-two-out parallel transfer transfer function should be added between the SPI and the double-track machine. The transplanting machine requests the board signal through the SIMIMA signal of the placement machine. At this time, the transfer machine will respond to the request of the placement machine to send the board to the first track of the placement machine. When the second track of the placement machine needs the board, the transplanting opportunity will pass the placement The chip machine SIMIMA signal requests the board signal, then the transfer machine will respond to the placement machine to request the board signal and send it to the second track of the placement machine (the signal is transmitted to the PCB board in sequence); when the reflow soldering is a single-track guide, the dual-track placement machine A two-in-one-out transfer machine is added between the reflow soldering and the transfer function (suitable for Panasonic, Fuji (FUJI), YAMAHA, Samsung, Siemens and other dual-track placement machines with one in and two out, two in one in one) out)

Classification:

Product serial number: 1347171716668477440

Product Description

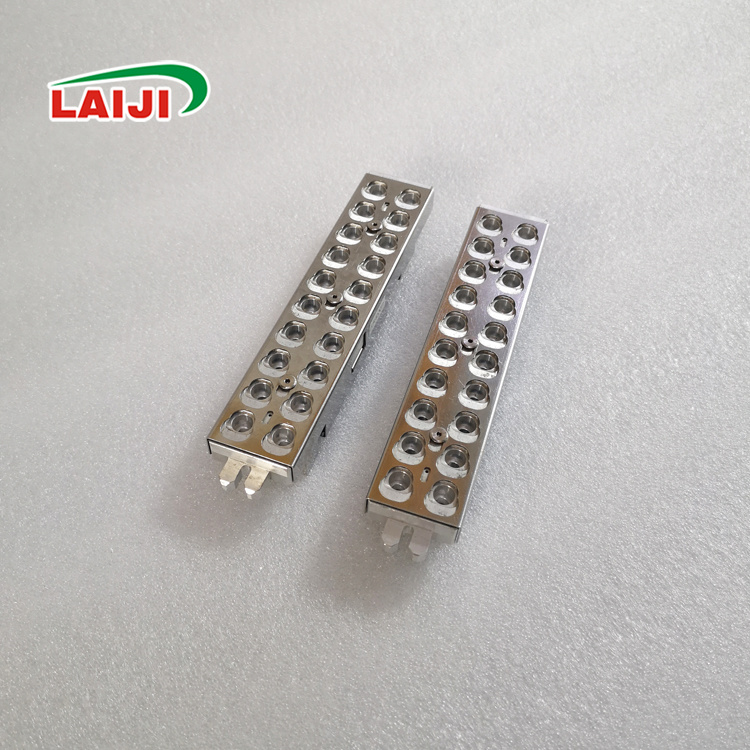

Carrier configuration

AdoptPanasonicPLC ,PanasonicOpticalCX442, LEF intermediate relay control system, stable and reliable operation.

Touch screen display operation, with fault sound and light alarm, automatic diagnosis function.

Stepper motor control, adjustable speed and distance.

Using imported steel wire belt drive, precise positioning and durable.

Using Taiwan Shangyin linear slide rail, good sliding, durable, accurate positioning,

A variety of models are available to meet a variety of production processes, the operation is simple and convenient.

The conveying height is 900mm±30

Using power:± single-phase 220V 50/60HZ 100W.

Single trolley drive stepper drive+stepper motor

Car guide rail transmission, double stepping motor transmission

First-in-first-out translation method

Closed design ensures the highest level of safety protection

The top safety cover can be opened to facilitate the handling of machine hardware during maintenance

Easy to use touch screen function control interface

Stable and balanced width adjustment device (hand-operated control screw adjustment)

The transfer distance can be set at will,

CompatibleStandard SMEMA interface

The top cover of the equipment is equipped with a visual window, which can safely monitor the production work status

The transmission distance can be set arbitrarily

The distance of the parallel transfer machine can be automatically converted to the weighing distance (settingPCB board width)

|

Serial number |

Scope of application |

|

|

|

Name |

Pan machine |

|

1 |

PCB board size (MM) |

50X50~500X300mm; |

|

2 |

PCB thickness |

0.6~3.0mm |

|

machine body |

||

|

1 |

Body size L*W*H (MM) |

600*1275*1000mm |

|

2 |

Body weight |

350KG |

|

3 |

Structure |

1.5mm steel structure, anti-static spray treatment on the surface, equipped with M16 shock-absorbing foot cup at the bottom |

|

Control system |

||

|

1 |

Power |

Single phase 220V |

|

2 |

Starting power/no-load power |

200W |

|

3 |

Compressed air |

5-6KG |

|

4 |

Fixed edge |

Front fixation (can be customized after fixation) |

|

5 |

Delivery direction |

Left to right (right to left can be customized) |

|

6 |

Transmission height |

900±50mm |

|

7 |

Repeat accuracy |

Can automatically calibrate accuracy and distance±0.5mm |

|

8 |

Transmission speed |

0~2m/Sec |

|

9 |

Withstand voltage |

AC terminal to ground 1500VAC, 1 minute |

|

10 |

Use environment |

No corrosive gas and dust environment |

|

11 |

Anti-interference |

Voltage noise: 1000Vp-p, bandwidth 1us, 1 minute |

|

12 |

Transfer and transfer |

Using stepping motor (42*48) |

|

13 |

Parallel transfer |

Using 86 high-precision stepping motor |

|

14 |

Pan drive |

Adopt 86 high-precision digital fan driver with cooling fan to work continuously, stable and reliable, and very strong |

|

15 |

Translational load transmission device |

Imported synchronous belt with steel wire (durable, high precision) |

|

16 |

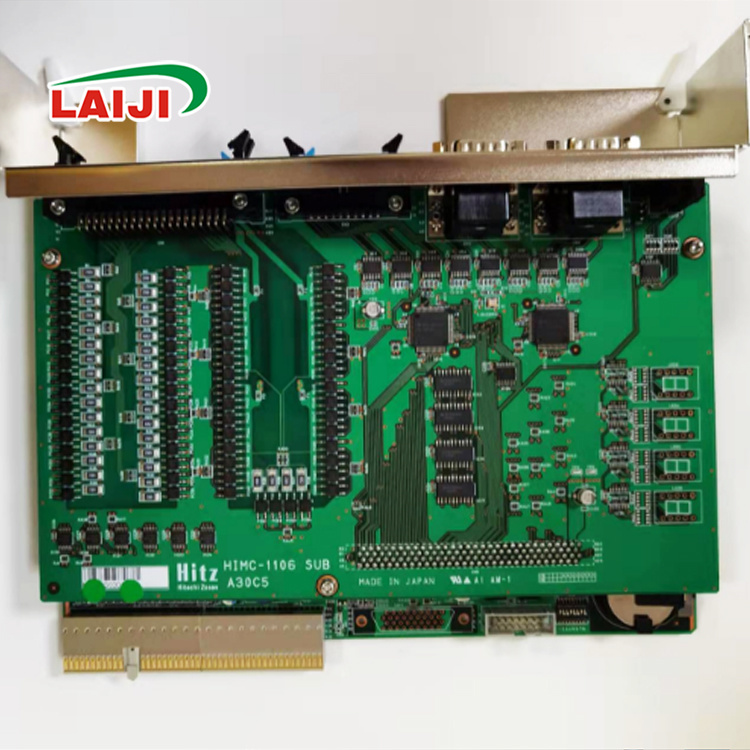

PLC |

Panasonic |

|

17 |

Touch screen |

Full color display control EA4.3 inch |

|

18 |

Groove photoelectric |

Omron |

|

19 |

Square photoelectric |

Panasonic CX442 or Swiss ELCO Optoelectronics |

|

20 |

Drive |

Xinlichuan Digital MT86, MT57 |

|

21 |

Anti-static belt |

3.8mm wide conveyor belt is used on the non-feng guide rail (anti-jamming function) |

|

22 |

Pan main line |

Imported high-speed, dismantling and wear-resistant special main line |

Key words:

Previous